Cartoon characters

- Arakhan

- Miti

- WINIZ

- Sanrio Characters

- Pinkfong

- Pororo

- Catch! Teeniping

- Shinchan

- Pokémon

- Shinbi Apartment

- Secret Jouju

- MUZIC TIGER

- Chiikawa

- Pinkfong Bebefin

- CoComelon

- Bubble Bobble

- Dinomecard

- Bread Barber shop

- Nai-B

- Dino-core

- CABEON

- Big pool float

- Tobot

- Among US

- Titipo

- Running man

- Robocar Poli

- Little Mimi

- Miniforce

- Miracle Melody

- Disney

- Milky

- Bakugan

- Beyblade burst

- Sandbox Friends

- Shining Star

- Sailor Moon Crystal

- Hello Jadoo

- Angry Birds

- LOL

- Butt Detective

- Octonauts

- Ghostmecard

- Ultaman Orb

- Jurassic Cops

- Cardcaptor Cherry

- Power rangers

- Carrie and Friends

- Tayo the little bus

- Pancoat

- Rilu Rilu Fairilu

- Pri Channel

- Hey Jini

Category

- Inflatable life jacket

- Neck swim tube

- Toddler Pool float

- Pool

- PVC ball and Rubber ball

- Arm band jacket

- PVC hammer and Arm floties

- Inflatable boat

- Water float mattress

- swim board and water float mattress

- Buoyancy aid

- swim goggles

- Snorkel

- Water gun

- Inflatable pillow

- Beach gown

- Air pump

- Swim diaper

- Dicapac

- Waterproof case

- Aqua shoes

- Bubble guns and others

- Dry bag

- Swim flap hat

- Swimfins

- Nai-B Daily

Waterpark & Resort

- Lazy river

- Inner tube for water slide - 1 person

- Inner tube for water slide - 2 people

- Inner tube for water slide - 4~6 people

- Inner tube for water slide - etc

- Buoyancy aids

- Inflatable signs for water park

- Inflatable boat

- Inflatable bounce house

- Inflatable roller

- Outdoor Pool

- Inflatable sledding

- Life-saving appliance

OEM&ODM

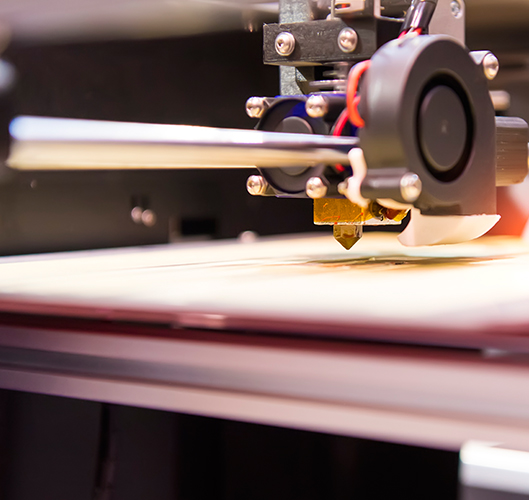

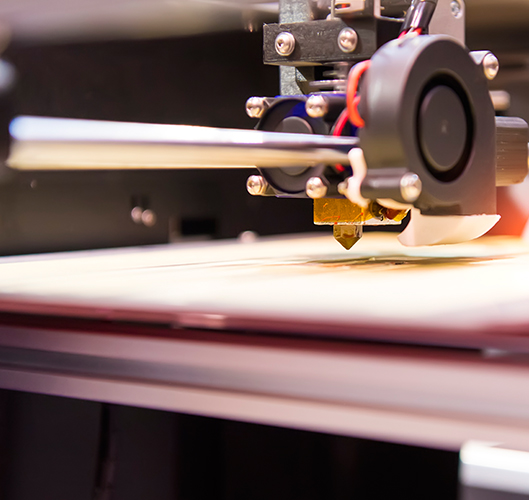

Manufacturing process

High frequency welding technique

Using high frequency induction heat source, heat or squeeze the PVC surface to create a design appropriate shape.

1. It’s possible to select only the parts you need to heat.

2. It’s possible to control the depth of heat treatment.

3. There is no carbon dioxide due to rapid heat treatment and rapid cooling treatment.

4. Surface heat treatment reduces the risk of damage and deformation of materials.

5. Large-sized products can also be heat treated in areas that need them.

6. It’s possible to process heat quickly and accurately at low cost.

Sewing technique

It is referred to as sewing machine and mainly produces life jackets.

1. By combining PVC products, more diverse production is possible.

2. It’s possible to produce products for special purposes such as buoyancy aids, special suits, bulletproof suits, and military vests.

Hot air welding & Bonding technique

It’s used in the production of multi-person water slide instruments and boats by strengthening tensile strength by forming a thick double junction surface with tarpaulin material.

One stop production system

Winnie Connie has established one-stop production lines with a number of patents and technologies to improve the completion of its products and shorten the production period.

Step 1. Planning & Design : Planning new products, developing products and attaching new features and packaging design

Step 2. Development & Production of Mold : Production of new mold for new planning products and OEM products

Step 3. Printing : silk screen printing

Step 4. High frequency welding & sewing : welding with PVC and PVC injection

Step 5. Test and packing : Package packing after total inspection or sampling inspection

Step 6. Logistics : Product delivery system in the warehouse

R&D

ODM and OEM production

Winnie Connie produces a variety of ODM and OEM products through molds and sewing processes. In order to respond immediately to customer requests, Winnie Connie can produce a variety of practical products in addition to water play goods. If you have any plans to develop household or safety products, please contact us.

Industrial property rights

From mold making to design development, we have consistently achieved development results such as registering industrial property rights such as design registration, trademarks and patents for water play goods.

|

|

|

|

|

|

|

|

Distribution & Sales

Large supermarkets

We provide water sports leisure products that have obtained quality certification standards for toys, baby products, and sports goods at large supermarkets in Korea such as E-Mart, Homeplus, and Megamart.

- The main products are pool floats for infants and toddlers, and various products such as swimming goggles, snorkel sets, ring tubes, boats, and mattresses for adults.

Water parks and resorts

Many water parks and resorts, including Vivaldi Park, Caribbean Bay, Blue One, and Resom Resort, are using Winnie Connie’s products.

- In these recreational facilities, multi-person inner tube for water slides and strong floats for lazy river, and life jackets that can be worn safely in wave pools are the main products.

Beach and Wholesale

You can also find Winnie Connie's products through many wholesale companies, including popular beaches such as Haeundae, Gwangalli, Daecheon, and Gyeongpodae Beach.

Character & Brand development

Miti

Let me introduce water play friend, "Miti". Miti is an all-around sportsman with excellent athletic skills, including swimming. So he also plays the role of a water safety guard who keeps everyone safe so that they can enjoy a fun and cool summer. Miti is the happiest and most fun friend to play in the water with her pretty girlfriend, "Biti." "Miti" is a brand of its own made by Winnie Connie. Winnie Connie strives to ensure the quality of its products, named "Miti," that matches MADE IN KOREA. Pure domestic brand "MITI 미티" guaranteed by Winnie Connie. It contains Winnie Connie's will to become the best in the water play industry with the honor of a pure domestic brand.

Arakhan

Arakhan is an official brand be a specialized company for sporting goods. To keep pace with increasing consumerism desire and trend of gentrification, Winnie Connie will cover entire water activity supplies beyond PVC products. Arakhan grafted Korean characters to emphasize its nature of being Korean company’s brand, and has a meaning of "King of the Sea".

Dynamic / Adventure / Exciting (Sub-brands)

Three brands are representative of Winnie Connie for a long time. These three are low-end products for general consumers among large floats and boats. It is produced directly by Winnie Connie's Chinese factory, and is presented with a different concept every year.

Winnie Connie Co., Ltd. develops and produces various types of character design products by signing contracts with many character licenses for more enjoyable leisure activities for children.

External activities

MOU with Industrial-Academic Cooperation Group

Winnie Connie signed an MOU with Dongseo University Industry-Academic Cooperation Group.

Exhibitions

Participation in domestic and foreign exhibitions.

Events to prevent water safety accidents

Participate in a water safety accident prevention campaign organized by the National Emergency Management Agency (Life jacket fashion show and donation event)